3D Printed modular shelf

Masters Program | Project Professor - Mary Polites

Completed: Fall 2024

Completed: Fall 2024

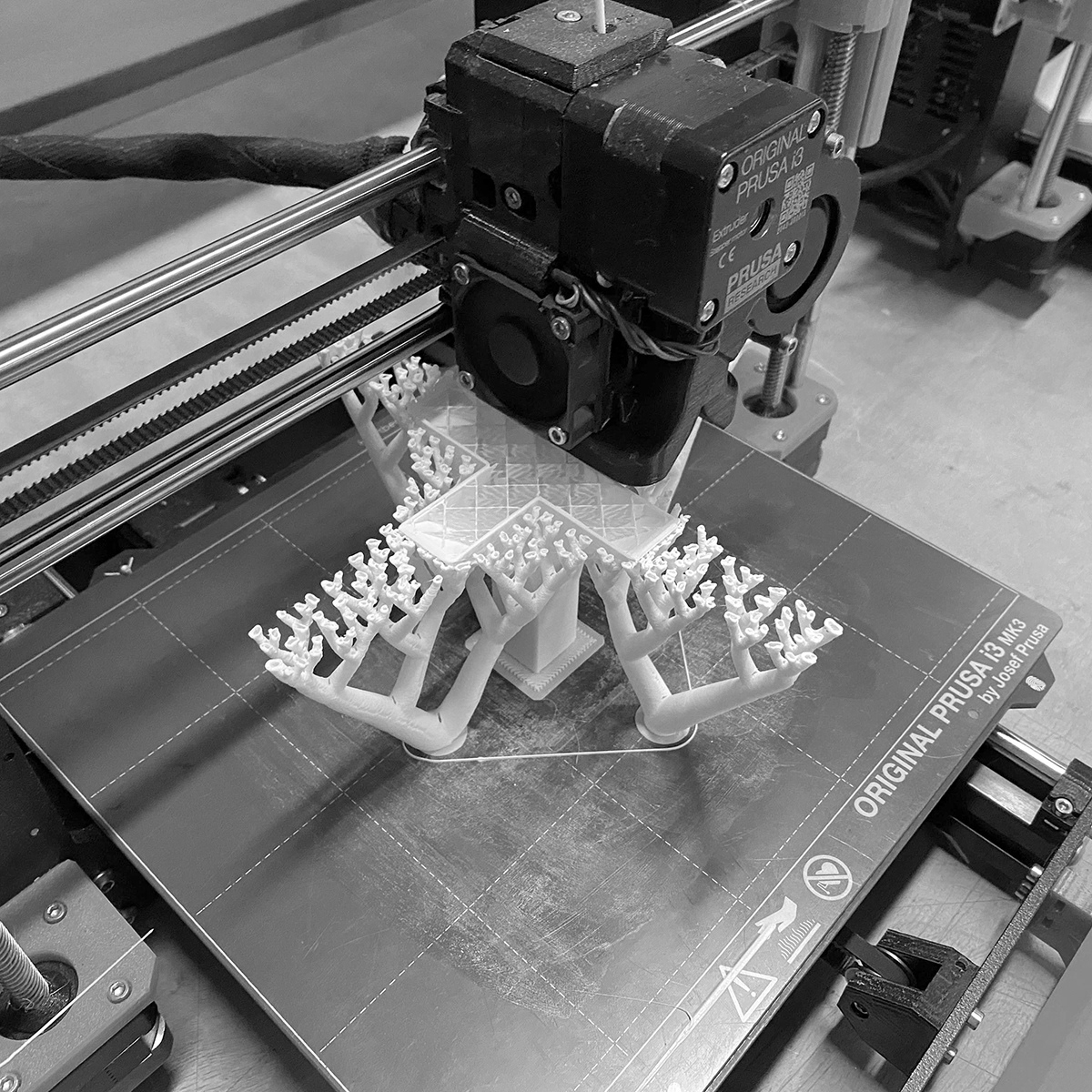

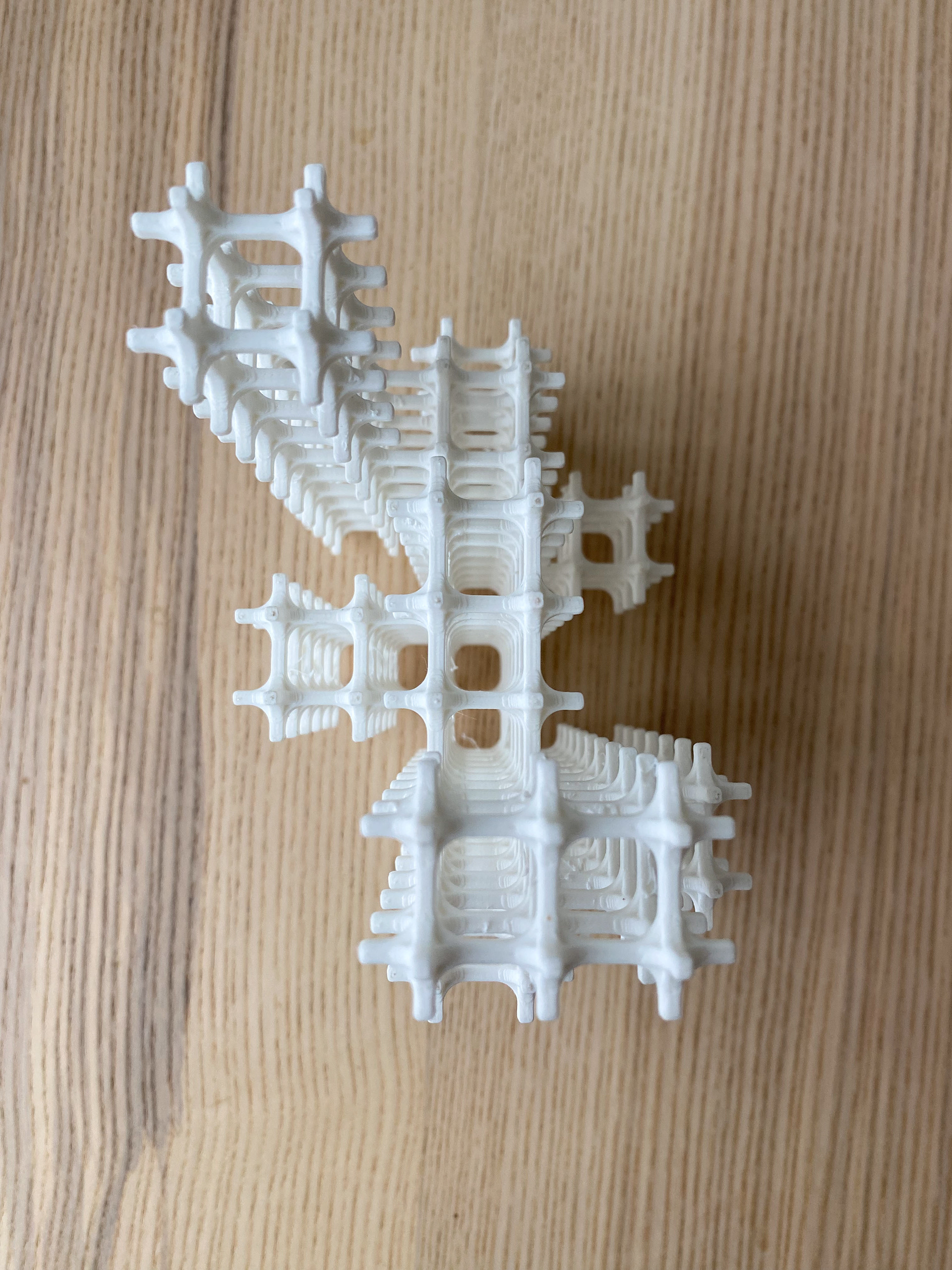

This modular shelf design utilizes a single primary piece and a series of connector components to create a flexible, expandable shelving system. All elements were 3D-printed using a Prusa MK3 printer and PLA filament. The primary shelf pieces, each measuring 7”x7”x7”, can be connected in any XYZ direction via the connectors. When four or more pieces are joined, they form a platform capable of supporting a shelving surface. The system accommodates larger items by varying the lengths of the connector pieces.

To demonstrate the concept, five primary pieces were printed, showcasing the system’s ability to expand in multiple directions and integrate shelving surfaces. Additionally, a 1”=1’-0” scale model of the complete design was printed to illustrate its full potential. Printing each primary piece required approximately 15 hours, while the scale model, with its complex cantilevered supports, took 30 hours to complete.

3D Printing Process